Ensuring Machine Safety Through Stop Time Testing of Safety Light Curtains

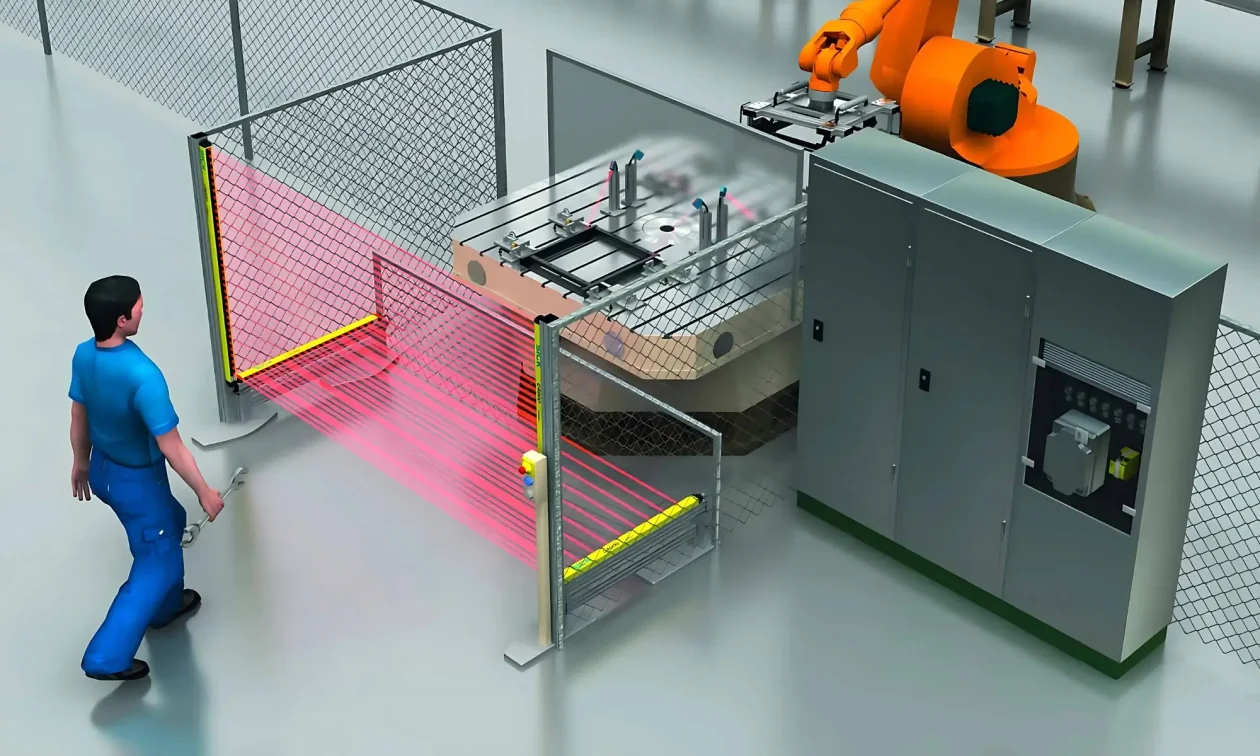

The use of safety light curtains has become an essential part of industrial safety systems across the manufacturing and automation sectors. These devices are designed to protect personnel from injury by halting dangerous machinery the instant a person or object enters a hazardous zone. However, to ensure these protective systems are working correctly, regular assessment known as stop time testing is required. Stop time testing verifies the speed and reliability of a machine’s stopping performance in conjunction with the safety light curtains to maintain compliance with safety standards and to safeguard the workforce.

Stop time testing is a critical process because safety light curtains do not stop the machine directly; they signal a stop command when the light beam is interrupted. The effectiveness of this protection depends on how quickly the machine can come to a complete stop after the signal has been generated. This delay, known as the stop time, must always remain within safe limits calculated for the particular setup. Over time, machinery components can wear, and reaction speeds can change, leading to longer stopping distances. Performing stop time testing at regular intervals ensures that the stopping distances remain within acceptable parameters so the safety light curtains continue providing reliable protection.

Proper calibration of safety light curtains is only part of ensuring their effectiveness. Even if they are installed correctly and the light beams operate without fault, this alone does not confirm that the associated machinery will stop in time to prevent an accident. Stop time testing offers a measured, data-driven way to verify that the overall safety system performs as intended. During testing, a technician measures how long it takes for a machine to stop once the safety light curtains have detected an intrusion. This time is then used to calculate the required safety distance between the hazard and the safety device. If the real stop time increases, the safety light curtains may need to be relocated to maintain compliance with safe distance regulations.

Safety light curtains rely on maintaining a calculated separation distance based on the response time of both the safety device and the machine being controlled. The equation used to determine this safety distance takes into account the speed of the operator’s approach, the stop time of the machine, and the response time of the safety light curtains themselves. If the measured stop time during testing rises beyond an acceptable limit, the protective zone must be expanded to maintain safety. This relationship highlights why stop time testing is not just a regulatory box-ticking exercise but a crucial activity in sustaining ongoing industrial safety.

In practice, stop time testing of safety light curtains is typically carried out using a digital stop time measurement instrument. This device measures the elapsed time between the interruption of the light curtain beam and the complete stop of the hazardous motion. The measurement process usually involves placing a test object or a reflective device into the detection field of the safety light curtains to trigger the stop command. The machine’s motion sensors or motor detectors then record the delay in stopping, producing an accurate reading that can be used to evaluate compliance with established safety distances. Results are documented, and any deviations from the standard performance are addressed through maintenance or repositioning.

Frequency of stop time testing depends on the operational conditions and the intensity of machine use. For systems that operate continuously or under high load, it is advisable to perform testing more frequently because wear and tear can degrade performance faster than in lightly used machinery. Safety light curtains form only one part of a broader safety system, and their effectiveness is linked to the mechanical and control components of the machine they guard. Regular testing ensures that all connected elements—mechanical brakes, solenoids, and control circuits—respond in harmony within the required time frame to prevent injury.

Maintenance routines and documentation play an important role in ensuring consistent performance of safety light curtains. Organisations should keep accurate records of every stop time test, including the measured results, testing dates, and any corrective actions taken. This documentation not only supports internal safety management but also demonstrates compliance with legal standards and audit requirements. If inspected by regulatory authorities, detailed records will confirm that safety light curtains are correctly tested, verified, and maintained within their certified performance range.

The importance of accurate measurement in stop time testing cannot be overstated. Even small timing errors can lead to miscalculations in safety distances, putting employees at risk. Testing technicians must ensure that the measurement equipment used alongside safety light curtains is properly calibrated and traceable to national standards. Proper calibration ensures the readings are consistent and reliable, allowing for precise calculations of separation distances. It is also important that environmental conditions—such as vibration, temperature variations, or dust accumulation—are factored into results, as these factors can influence both sensor performance and machine responsiveness.

Training personnel involved in the operation and testing of safety light curtains is another essential element of a safe workplace. Employees must understand how safety light curtains function, what their limitations are, and how stop time testing contributes to their reliability. Training helps operators identify early signs of issues such as sensor misalignment, wiring faults, or increased stop times that might go unnoticed in routine use. In many cases, a small irregularity detected early through observation and testing can prevent more serious safety faults from developing later on.

From a strategic perspective, implementing a consistent schedule for stop time testing demonstrates a proactive safety culture. Safety light curtains are preventive devices, but their efficiency depends on ongoing verification. Establishing clear responsibilities for testing, record keeping, and corrective actions fosters accountability while minimising downtime and incident risk. In industries such as automotive manufacturing, metal processing, and packaging, where operators work in close proximity to moving machinery, reliable performance of safety light curtains is essential. Regular testing can also extend the operational life of equipment by identifying potential control or braking issues before they cause costly failures.

As automation advances, safety light curtains are being integrated into more complex safety control systems, often communicating with programmable safety controllers or robotic cells. In this context, stop time testing becomes even more valuable. The more complex the system, the greater the number of variables influencing overall stop time. A modern production line might include coordinated movements between multiple axes or synchronised robots. Each connection adds layers of delay potential, meaning that stop time testing must evaluate the entire control chain from the moment the safety light curtains detect an obstruction to the full stop of all moving parts. This holistic testing ensures that complex arrangements remain safe and predictable.

In addition to verifying stopping performance, stop time testing can help optimise production efficiency. By establishing precise stopping distances, operators can configure safety light curtains to provide maximum working space without compromising protection. This balance between safety and productivity is important in environments where space constraints and workflow efficiency are paramount. A precisely tested and calibrated system means operators can work closer to the machines within safely calculated limits, avoiding unnecessary interruptions while still maintaining strict safety compliance.

Even though automation technology continues to evolve, the fundamental principle behind safety light curtains remains the same: preventing harm through rapid detection and response. Stop time testing secures this principle by confirming that what is supposed to happen in theory holds true in practice. Without such verification, operators would rely purely on manufacturer specifications, which might not reflect the actual performance of an ageing or heavily used system. Stop time testing acts as a reality check, showing whether the equipment still performs at the speed required to protect users.

For new installations, initial stop time testing should form part of the commissioning process to establish baseline data. This first measurement provides a benchmark for future comparisons during ongoing maintenance cycles. Over time, subsequent readings can be compared against the baseline to identify gradual performance degradation before it reaches a dangerous level. These comparisons enable planned maintenance rather than reactive fixes, improving efficiency and reducing downtime. When safety light curtains and their controlled machines are maintained in this way, the result is a safer, more reliable production environment.

The future of stop time testing may include advanced digital monitoring that continuously tracks response times within safety systems. Sensors built into control hardware could automatically record stopping times, triggering maintenance alerts when performance begins to drift. Such innovations would complement traditional safety light curtains by adding predictive capabilities, ensuring safety remains proactive rather than reactive. Nonetheless, manual verification through proper testing procedures will always play an important role, confirming that all system components operate exactly as intended and within safe parameters.

Ultimately, stop time testing provides the confidence that safety light curtains are functioning at their best. They protect people not just because they detect movement but because they trigger a response chain quick enough to prevent injury. Without precise, regular testing, even the most advanced safety light curtains could lose effectiveness unnoticed. A well-maintained testing schedule, combined with accurate documentation and commitment to continuous improvement, ensures ongoing protection, legal compliance, and peace of mind for both operators and employers alike.