Expert Tips for Selecting Durable Deep Groove Ball Bearings: Focus on the SKF 61804

Finding high-quality deep groove ball bearings might be the difference between a system that operates accurately and one that wears prematurely under stress. Understanding what constitutes a truly trustworthy bearing is critical for anyone dealing with industrial machinery, engineering designs, or maintenance operations. The SKF 61804 is generally acknowledged for its consistency and durability, and it serves as a benchmark for what deep groove ball bearings should give in terms of precision, efficiency, and lifetime.

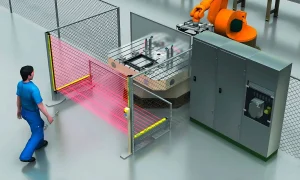

Deep groove ball bearings, like the SKF 61804, are essential components in mechanical design. Their adaptability allows them to manage radial and axial loads with minimal friction, making them appropriate for a wide range of applications, including electric motors and automation equipment. When looking for a high-quality bearing, consider material composition, manufacturing precision, lubrication quality, and tolerance consistency. The SKF 61804 exemplifies these characteristics with its thorough engineering and stringent testing requirements.

Surface finish is a defining feature of a high-quality deep groove ball bearing, such as the SKF 61804. The raceways and balls have been polished to such precise tolerances that friction is minimal even under large loads. This provides smooth operation, less noise, and a longer service life. When analysing a bearing, subtle factors like surface quality refinement and cage construction perfection might tell significantly more about performance than marketing claims. The SKF 61804 demonstrates thorough control over these variables, resulting in the type of performance reliability required in industrial situations.

Temperature tolerance is another important consideration in the search for high-quality deep groove ball bearings. The SKF 61804 is engineered to work reliably under a variety of temperature situations. Excessive thermal expansion or contraction in bearings can cause shaft misalignment or unnecessary load, resulting in premature failure. However, well-engineered versions, such as the SKF 61804, maintain their internal clearances even under changing conditions, assuring consistent rotational performance. This feature is extremely useful in applications that need high speeds or exposure to temperature changes.

The durability of the bearing is also determined by its material composition. The SKF 61804 is normally made of high-grade steel that has been developed to be robust and corrosion resistant. Inferior bearings frequently appear identical on the outside but lack the metallurgical consistency found in premium types. This causes micro-pitting or early tiredness. The intelligence behind a dependable bearing resides in the exact regulation of carbon content, heat treatment, and grinding accuracy. The SKF 61804 is an example of how these internal components combine to provide a bearing capable of long-term performance, even in difficult conditions.

Noise and vibration levels are also important factors in determining bearing quality. A correctly made deep groove ball bearing, such as the SKF 61804, will rotate quietly and smoothly, suggesting balanced construction and precise geometry. Excess noise frequently indicates raceway flaws, unequal ball loading, or lubricant contamination. Users can be confident that by investing in precision-made bearings such as the SKF 61804, their machinery will experience less vibration transmission, resulting in smoother operation and enhanced operator comfort, especially in high-speed or sensitive equipment.

Lubrication quality has an equally important impact on performance. The SKF 61804 employs sophisticated lubrication formulas intended to reduce wear while preventing degradation over time. Lubricant breakdown can expose internal surfaces to frictional heat and corrosion, significantly shortening bearing life. When choosing a bearing, ensure that its lubrication meets the operating temperature, load, and speed requirements. The SKF 61804 stands out for its mix of seal design and lubricant retention, which ensures protection while decreasing drag and allowing it to work well over lengthy operation cycles.

Another technical indicator of deep groove ball bearing performance is dimensional correctness. The SKF 61804 meets high international standards, with internal clearances, ball sizes, and raceway curvature tested to micrometre precision. This level of control not only provides interchangeability, but also allows engineers to accurately forecast performance across assemblies. If a bearing does not satisfy these strict tolerances, even tiny deviations might result in imbalance, energy loss, or shaft misalignment. Precision manufacturing, as demonstrated by the SKF 61804, avoids these dangers while preserving mechanical efficiency.

It is equally important for firms and individuals sourcing bearings to check authenticity. The global market comprises counterfeit or substandard products that resemble genuine bearings. When dealing with components such as the SKF 61804, the difference between genuine and counterfeit might mean thousands of hours of dependable service vs unexpected and costly downtime. Always purchase bearings from authorised channels or vendors who provide full traceability. The SKF 61804 is popular among professionals since it represents constancy in both performance and provenance.

Load capacity is an important consideration when selecting a deep groove ball bearing. The SKF 61804 combines a compact design with a strong load-carrying capacity, allowing it to work effectively in configurations with both radial and axial forces. Its interior shape is designed to transmit stress equally across contact points, minimising premature wear that is frequently caused by unequal load distribution. Machine designers frequently choose bearings like the SKF 61804 because of its consistent performance, which simplifies modelling and dependability calculations during system design.

Corrosion resistance also has an impact on bearing longevity, especially in settings with high moisture, chemical, or airborne contamination levels. The SKF 61804 uses improved steel compositions and surface treatments to defend against rust and oxidation. This makes it acceptable for use in a wide range of applications, including industrial machinery, transportation systems, and even environmental control units, where exposure could deteriorate lesser bearings. Investing in corrosion-resistant bearings, such as the SKF 61804, ensures long-term performance with less frequent replacements.

Maintenance requirements must never be disregarded. Bearings like the SKF 61804 are designed to require minimal maintenance once installed, as long as the surrounding components retain appropriate sealing and alignment. Over-lubrication or contamination often reduces lifespan, however the SKF 61804’s sealed construction helps to prevent dust and debris entry. A regular maintenance program, combined with cautious installation techniques, will allow users to fully utilise the bearing’s sturdy engineering. Simply installing a high-quality bearing without considering fit, cleanliness, or shaft finish defeats the advantages of its superior design.

Speed ratings distinguish regular bearings from high-performance ones. The SKF 61804 has outstanding high-speed capabilities thanks to its precise production and refined internal design. When machinery operates at high speeds, even minor flaws might result in overheating or imbalance. Bearings like the SKF 61804 ensure smooth rotation and stability at high revolutions per minute, giving confidence in applications where energy efficiency, noise reduction, and long-term durability are critical.

The procurement procedure should be as thorough as the engineering itself. When analysing deep groove ball bearings, keep the supplier’s reputation, packing integrity, and identification markers in mind. The SKF 61804 provides unambiguous and verifiable product numbers, ensuring traceability. For engineers and buying experts, this transparency improves inventory management and quality assurance audits. The peace of mind that comes with knowing a bearing can be traced back to its source cannot be stressed in industries where safety and performance rely on dependable mechanical components.

Cost considerations are common when selecting bearings, but seeing the SKF 61804 as a long-term investment allows for a more realistic assessment of value. Cheaper solutions may sound appealing at first, but they can lead to frequent malfunctions, increased energy expenses, and unnecessary maintenance. The SKF 61804, with its proven endurance, lowers total lifespan costs by requiring fewer repairs and reducing operating disruptions. Evaluating quality bearings based on entire performance rather than initial outlay allows for a more reasonable purchasing decision, especially in industrial or production environments.

Testing and certification confirm the reliability of premium bearings. The SKF 61804 is submitted to extensive testing processes to ensure compliance with international mechanical and dimensional requirements. These tests evaluate fatigue resistance, rotational precision, and noise levels under a variety of loads. Users looking for deep groove ball bearings should always examine available technical documentation and compliance certifications before purchasing to verify they satisfy the necessary operational standards. The uniformity of test results is one of the factors that identifies the SKF 61804 as a reliable choice for engineers.

To summarise, selecting high-quality deep groove ball bearings needs more than just scanning a specification sheet; it also necessitates an awareness of the technical details that characterise performance. Surface finish, tolerances, lubricant integrity, and load carrying capabilities are all factors that influence longevity and durability. The SKF 61804 is a reliable reference point for these characteristics, indicating the high quality that any engineer or buyer should pursue. By focussing on verified authenticity, reputable suppliers, and accurate construction, you not only protect your equipment but also improve operational efficiency for years to come.