Modernising Mechanical Services: The Rise of Packaged Plant Rooms

Reliability, speed, and efficiency are of the utmost importance in the complex realm of contemporary building services. Conventional on-site mechanical and electrical infrastructure construction methods frequently provide substantial obstacles as project complexity and deadlines tighten. This is where packaged plant rooms shine as a game-changing solution for delivering essential building systems. Modular units that incorporate a variety of plant equipment—including pumps, boilers, chillers, heat exchangers, and control systems—are known as packaged plant rooms. These rooms are custom-made and typically pre-commissioned.

The idea of packaged plant rooms is both incredibly striking and extremely simple. Construction, design, and testing of these mission-critical systems take place in a controlled factory setting rather than inside a building’s shell. From the very beginning of the design process all the way through to the end of the project’s operation, this off-site manufacturing method has several positive effects. The engineering accuracy and quality control measures that can be implemented in a controlled industrial environment are frequently superior to those that can be used on a live building site, which can be somewhat unpredictable.

The dramatic shortening of project durations is among the most alluring benefits of packaged plant rooms. Concurrent manufacturing of the plant room and civil works and building construction can take place on-site. The elimination of many sequential dependencies made possible by this parallel processing significantly speeds up the overall completion of the project. Minimal installation effort is required for a packed plant room once it is delivered to the site. This typically involves connecting to main services and final commissioning, which significantly reduces the amount of labour and expenses involved with on-site labour. Developers and clients that want to limit interruption and get their facilities online faster are drawn to this rapid delivery.

In addition to speed, packaged plant rooms provide unrivalled quality and consistency. Expert professionals carry out each weld, pipe run, and electrical connection in an optimal setting. Problems with bad weather, crowding, and uneven skill levels are less likely to occur in this controlled setting than on more conventional building sites. The end product is a solid system that can withstand heavy loads during commissioning without breaking a sweat. When the packaged plant rooms are fully installed in the building, this intrinsic quality instantly transfers to improved operational reliability.

Another essential advantage of packaged plant rooms is their adaptability in terms of design. Small, compact units for urban infill projects and large-scale multi-module systems for enormous commercial or industrial complexes are both possible with their engineering. Because they are modular, the packaged plant rooms can be altered to fit the specific dimensions and layout of any given structure, meeting both aesthetic and practical needs. Because of their versatility, they can be used in a wide variety of settings, including as residential projects, hotels, schools, data centres, hospitals, and more.

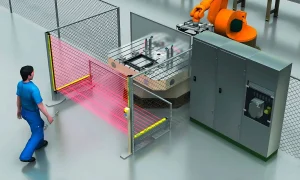

In addition, site safety is greatly enhanced with the installation of packaged plant rooms. Reducing the amount of people, tools, and materials needed on the active construction site is possible by outsourcing mechanical and electrical installation work to a factory. This eliminates potential hazards, streamlines operations on the job site, and makes better use of space that would otherwise be taken up by tools and supplies. An environmentally safe work site not only helps get things done faster and with less expense, but it’s also the right thing to do from a moral standpoint.

Additionally, packaged plant rooms have strong environmental benefits. Since off-cuts and surplus materials can be recovered or reused more easily at a factory, it usually results in less waste than on-site fabrication. Minimising the chances of damage or loss, the controlled environment also enables precise material management. Additionally, these pre-assembled units help reduce operational carbon footprints for the buildings they service due to their inherent efficiency, which is generally designed with best energy performance in mind. Modern building practises increasingly necessitate this dedication to sustainability.

Reduced manpower and accelerated completion are only two of the economic benefits of packaged plant rooms. Because of the superior installation and the lack of maintenance required, lifecycle costs tend to be lower. Regular service and problem identification are made easier with all components laid out and accessible, which results in reduced downtime and more predictable operational expenditure. If possible, standardising designs across projects could lead to even more cost savings and simplified procurement processes for packaged plant rooms.

It’s quite easy to set up packaged plant rooms. They are usually hoisted into place after they arrive at the location, whether that’s on a rooftop, in a basement, or even at ground level. It usually just takes a few hours for a single module, thus the procedure is lightning fast. This lessens the impact on nearby regions and makes the logistical hurdles of getting heavy machinery to a crowded construction site much easier to handle. Projects with limited space or restricted access can benefit from packaged plant rooms due to their easy positioning.

Another major improvement is the ease with which packaged plant rooms can be commissioned. The factory can pre-test and pre-commission much of the internal wiring, pipes, and control logic, drastically cutting down on the time needed to commission the system on-site. This guarantees that the systems are completely functional considerably more quickly, saves time, and lessens the likelihood of last-minute problems. To make sure that packaged plant rooms work well with the rest of the building services network, this pre-validation is essential.

Future plans call for packaged plant rooms to play an even larger role. The capacity to prefabricate and pre-test intricate configurations will be of utmost importance in the future due to the increasing need for smarter and more integrated building systems and the rapid evolution of related technology. A facility that makes packaged plant rooms is the best place to handle the integration of renewable energy interfaces, modern control systems, and monitoring equipment. They are a smart choice for the performance of buildings in the long run because of their ability to withstand changes in the future.

To sum up, the introduction of packaged plant rooms has completely changed the way mechanical and electrical infrastructure is delivered. They provide an attractive alternative to conventional on-site construction in terms of speed, quality, safety, and cost-effectiveness. There is no denying the many benefits, including shorter project timeframes, increased site safety, better build quality, and decreased lifecycle costs. The growing popularity of packaged plant rooms is more than simply a passing fad; it represents a sea change in the way our vital services are built and run, and it’s a direct result of the construction industry’s relentless pursuit of new and better ways to complete today’s projects. Packaged plant rooms will continue to be popular in intelligent and sustainable building techniques in the UK and abroad thanks to its adaptability and inherent efficiency.